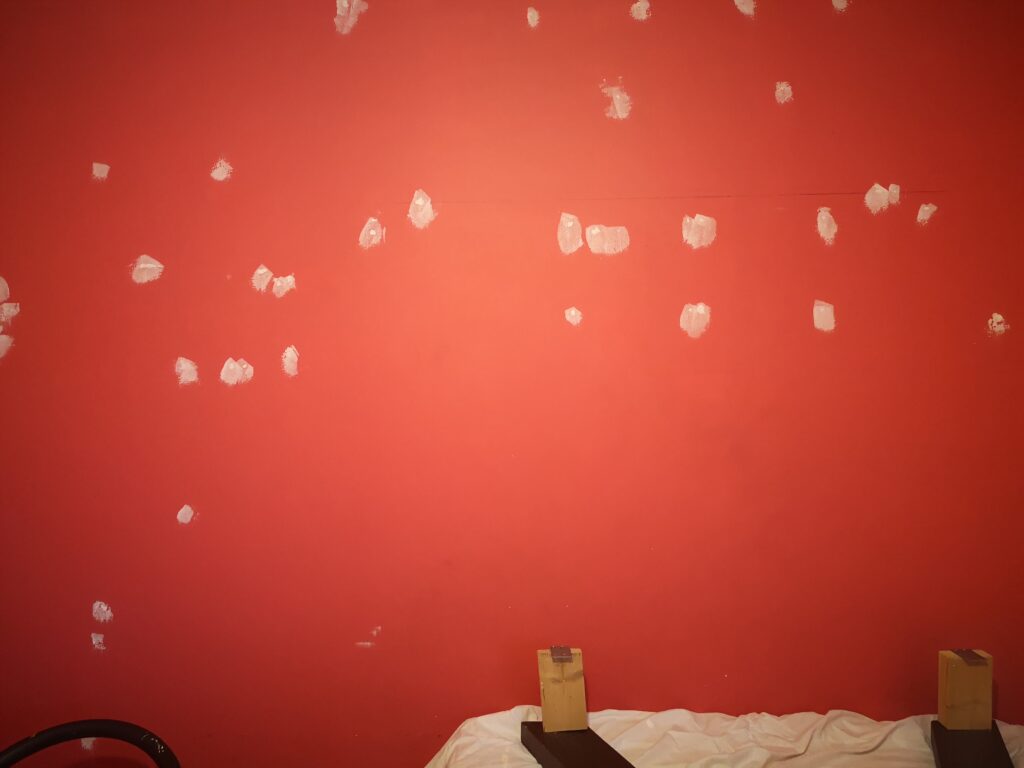

So the playroom is now painted, looking nice and fresh. Scaffold is on order, to be delivered shortly. And for ease (and because I like new tools) I also acquired a portaband – a handheld metalworking bandsaw.

OK, this isn’t really an “ABDL” project, it’s more a generalised kink one. But I’m not building a whole new website just to write this up on.

Backstory:

My partner has a playroom cum guest room at their house and while moving some things to work on adding Segufix mounts to the bed in there, we spotted a little mildew on some of what’s being stored between the bed and wall. So we figured, it might be best to move the bed so it’s not on the outside wall, which then got us talking about moving the storage for other toys. That means unscrewing things from the wall, leaving unsightly holes.

Project outline:

So, that means it’s decorating time. After that, since we fancy having suspension points available, time to build a frame for that out of scaffold poles, giving a sort of industrial feel. The frame is going to fit to the room, so there’s still space to use other toys without needing to dismantle it.

First, time to fill holes and sand. Then sugar soap and paint.

While that’s happening, time to work out the scaffold frame and order the connectors and scaffold tube for it.

To that end, I built a model, as drawing it as a plan of any sort doesn’t cover everything. I gave up modelling all the diagonals, it got too complex.

So, a photo from around the end of the last stage. I’ve cut round the taps – this proved to be awkward to cover later, but I’m not sure anything else would have been better. I might revisit this – creating another panel that worked with the rest would be possible.

Now some progress. I purchased some 2 inch foam sheet (panels?) from Dunelm as well as some PVC coated fabric for a wipe clean covering. I just guessed on 2 inch being enough, I really didn’t want to go up and use 3 inch and it seems comfortable enough.

With the foam cut to size, on to the covering to made it wipe clean. A traditional approach here – pinned in place with brass tacks. Now, getting actual solid brass tacks wasn’t easy (I ended getting them via Etsy Studio) but I really don’t want anything that will rust – so the cheap steel ones are ruled out. Corners are folded in, making sure the extra layers sit on the ‘end’ of the boards – rather than adding to the width, where the distances are more critical in fitting all three boards in the set space.

The last board gave some trouble in this regard – eventually I ended up with the main section wrapped around the edges are all but one side of the cut out for the taps. The final side of that was covered with an additional piece which runs over the first layer and down the end of the cut out to cover the last section of foam. Possibly not the best but closest I could figure out – and didn’t require any sewing.

Still to add are some blocks underneath to prevent the boards sliding, and a victim volunteer who tested it suggested some securing points would be a good idea. I had been thinking of one or two, but possibly that’s going to be increased, making this a rather kinky changing table. Possibly even something above to allow legs to be lift easily (and held if desired!).

More updates to come, although it has already seem some (careful) use as is.

For a while I’ve been thinking about how I’d fit a change table in. I live in a small flat, so there’s not really space to fit a dedicated, permeant 6 foot table in. I’ve toyed with the idea of folding ones in various designs, but actually there’s not a huge amount of space to put them up in and actually use them.

Recently I hit upon a plan to reuse a mostly neglected space – it isn’t a full 6 foot but it works – the bath tub! Hang on, how can this work you ask? Remarkably simply! The height of my bath is sufficient that the top edge is about the height for the top of the changing table. Simply place boards over and we have a solid base.

So, I measured up the length and width of the bath – ignoring the taps, I’ll fiddle that later. Got a sheet of 18mm exterior rated plywood (it is know to occasionally be wet in bathrooms!) and had it cut down to my measurements – much easier to handle that way, unless you’re blessed with equipment and space to handle the full 8×4 sheet. 18mm ply is thick enough that it only flexes by a few millimetres when I stand in the middle of each board when it’s over the bath, with no other support or reinforcement needed – plenty it won’t give way even with heavy littles on it.

Back at home I then further cut the panel into 3 sections, to make it easier to move and store – 55cm wide for each of mine, it’ll depend on the size your bath is. For the final board I then marked out the area the taps took up and cut that out with a jigsaw, so it fits either side. Then sealed the wood as I don’t want it absorbing water – polyurethane yacht varnish/enamel is ideal, give it at least a couple of coats all over.

Finally back for a trial fitting, just to make sure everything lines up, and a quick lie down on it for a small test. Next steps: including some form of padding on the top for littles comfort, a wipe clean covering. I think also I need a system for stopping the panels just sliding off the edge of the bath as they aren’t then properly supported – possibly as simple for me as a strip of wood on the bottom in the right place. Fortunately both ends of my bath end with a wall so no worries about the panels slipping off the end.

OK, as promised in the last post – photos.

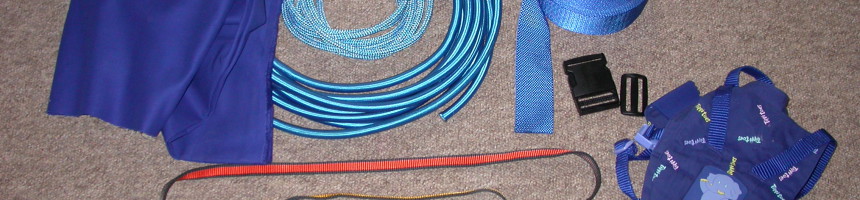

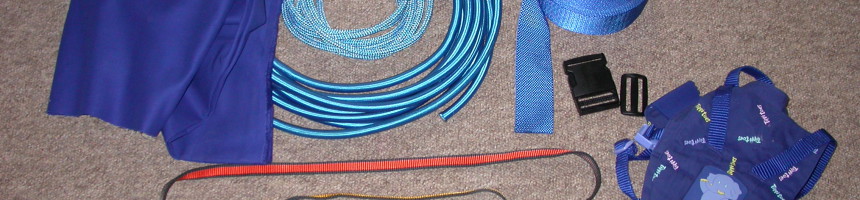

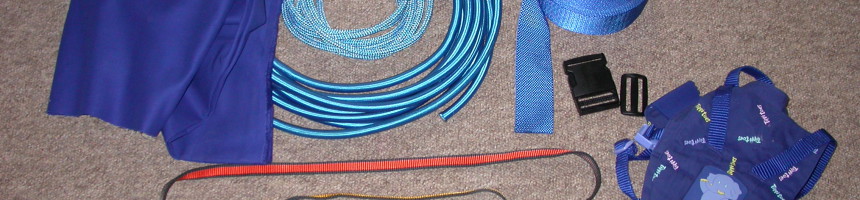

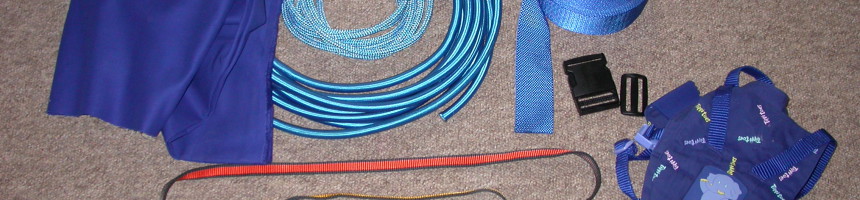

First, a quick pic of the materials so far. Lower right is actual baby bouncer I purchased – just the harness section is shown here. Moving clockwise we have the climbers webbing loops for fixing up to such bars as we have access to, a representative sample of the material for the harness, lying over the bungee cord – 12mm diameter. Inside that we have the lighter blue/speckled white rope – this stuff is amazing, it’s strong like steel wire. Next to them we have the webbing to complete the harness and the buckles I’ll be using to strap the little in. Missing from the picture is the massive bundle of wadding to pad the harness with. The carabiners are yet to be ordered but shouldn’t be too complex to source (except my links to ScrewFix in my earlier post are now broken so it’ll need some research again).

Here’s a close up of the baby sized bouncer I bought to steal measurements from – all detached from the rest of it which frankly isn’t as interesting. And below is the pattern I made by carefully scaling it up by 2.5 times the size to make it adult sized.

I’ve now carefully transferred the pattern to a section of my material – I have plenty of spare should I need to treat this one as a prototype. I’ve carefully pinned it ready to sew up with another layer and get the core of the harness built. More photos soon when I get started on that, should be this weekend.

OK, a quick update, I keep meaning to give a fuller update and not getting to it.

I now have a whole pile of items for this project – I’ll get a photo up shortly.

I stumbled upon an actual baby bouncer in a charity shop so quickly grabbed it as a design template. From other things I have heard suggested scaling by a factor of 2.5 times – effectively measure the baby version in centimeters and use the same numbers but make yours in inches. Having stuck some large paper together I drew out a paper pattern and it seems to be the right size – like magic. Photos and details of the pattern will follow.

Having got a pattern, I’ve drawn up the outline on some fabric and then I need to get cutting and sewing – which has somehow fall to the side somewhat.

More info, photos and details soon, I promise.

Today I bring you not news of my own bouncer but photos and details of another bouncer, many thanks to Baby Robin. It’s always interesting you see details of other similar projects, theres often a lot to learn. It pays to avoid making the same mistakes, then you’re free to make different ones. Now on to the detail.

The harness was custom made by No Escape. The main straps run from the top back through the crotch-area to the front. Since they must bear all the weight (including the bouncing), it uses wide canvas belts like used in straight jackets.

The belts on the side and over the shoulders do not bear any weight, so for easy access and adjustability can be opened.

Since the shoulder straps are adjustable and thus can not bear the weight (and to maximise height for the bouncing effect) the bungee cord (4 x 10mm on each side) are fitted to the D-rings directly onto the harness. The bungee cord is the same used for trampolines and can be ordered by meter online.

Initially the design had a spreader bar, but this caused a problem with the total height, so this was then changed to double suspension with the bungee cord going directly from the harness to the frame. As this means the bouncing happens in the opening between the top bars this gives much more height for bouncing in.

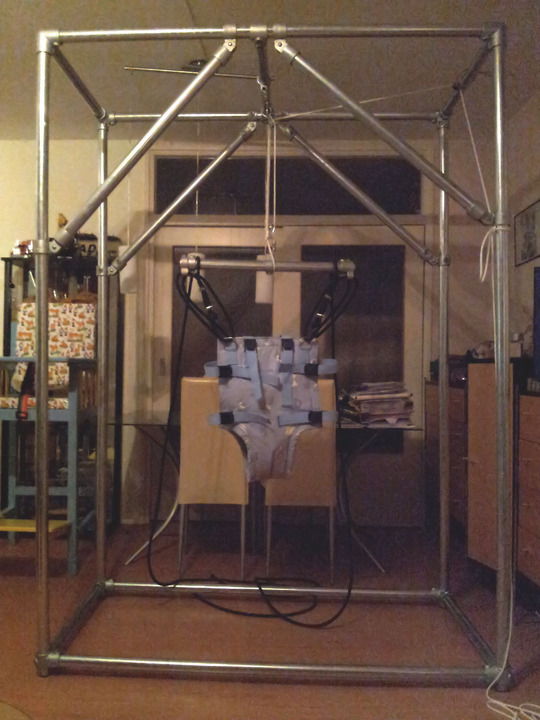

The stand is constructed from 3,25mm thick round, galvanised steal tubes (42.4mm diameter) with tubing clamps. Total height is 230cm, 70 cm deep and 150cm wide. It is calculated to hold 500KG, since bouncing can have greater force than just the weight – up to triple according to Robin.

Robin also reports that since all the weight is held via the two crotch-straps in the harness, it can become somewhat uncomfortable for men when bouncing for an extended period (longer than 10 minutes). Just hanging is apparently no problem. Robin has no solution yet, he also notes climbing harness have the same issues – something I can confirm! I’ll be thinking about padding and spreading the load in this area to minimise this in my design. Another option is to relieve some of this pressure by forcing other areas to provide some support – under the arms is the next obvious place, although I’m sure this could also be uncomfortable after some time.

Robin’s solution to height is very practical, I’d decided to ignore this completely as I was going for closeness to the original baby design as possible. This was possible due to having a venue in mind with high enough support points – although this limits the possibilities for testing.

A few days ago I randomly found a better option for one of my component parts.

I’m swapping out the idea of using a cargo sling for a rock climbing nylon webbing sling. They’re rated at higher loads and are designed for holding people up after all.

Source for them is Amazon. I’ve gone for one at 30cm and one at 60cm – obviously the size needs to be right for what you’re attaching to. Hopefully I’ll get blue ones to match the rest of the bouncer, sadly don’t get to choose in this case.

Having got an idea of the design we’d like, lets get looking at what we’re making it from! We don’t need a full list just yet, there’s always room for changes as we proceed but we might discover something to save us some time!

I think that covers most of the major elements. Now, in many ways the most complex bit is the seat – it’ll need most ‘assembly’ as it’ll need each element stitching together. On top of that it’s probably going to need the most ‘design’ – it needs to combine an inside fabric, padding, straps, outer layer, buckles to keep the little in safely. Since this is all going to take time, that’s what we’ll be doing next.

Note:

‘Adult sized baby door bouncer’ doesn’t quite roll off the tongue – and no doors (or doorways) are likely to be involved in this ones use – so I might just refer to this as ‘The bouncer’ or ‘Project 1’ from now on.

Now, although I don’t want to do a fancy ‘design brief’ and make this all formal, it’s always good to get the basic requirements and thoughts down before you start work.

Now, obviously a diagram is helpful – on some projects it’s all I use. Often just a sketch with some notes scribbled on. (As you can see from the artistic master piece below!)

Now, some thoughts on the requirements. For this project there’s quite a few of these, it’s not easy to draw this stuff on the diagram!